This study’s objectives were to assess the quality of treated municipal wastewater (TMW) used for irrigation of commercial vineyards and to quantify the amount of plant nutrients applied via TMW irrigation. In this regard, the study formed part of a long-term project to assess the sustainability of using TMW for vineyard irrigation in the Coastal region of the Western Cape.

Introduction

The climate of the Western Cape is particularly suitable for producing grapes and supports a very productive wine industry.1 However, freshwater resources are generally limited in the grape-growing districts. Consequently, sustainable grape production in the province is highly dependent on winter rainfall and the application of irrigation in drier regions. In this regard, inconsistent rainfall and periodic droughts can severely impact the wine industry. Low annual rainfall, limited supply of fresh water that can be stored on farms, and water restrictions imposed by authorities have highlighted the necessity for alternative water sources for vineyard irrigation for the South African wine industry. Many arid and semi-arid countries use TMW as an alternative source of irrigation water. It is particularly suitable as an irrigation water source in Mediterranean countries with limited freshwater supplies during warmer months and high rainfall during winter. This can facilitate the leaching of salts applied via wastewater irrigation. However, no studies have yet assessed the feasibility of using TMW rather than fresh water for vineyard irrigation under South African conditions.

Using TMW for irrigation has several potential benefits and disadvantages.2 As a source of additional water, it can improve and sustain crop production. It often contains high amounts of essential macro-elements such as nitrogen (N), phosphorus (P) and potassium (K+) that can be recycled if applied via the irrigation water. In addition, irrigation using K+-rich wastewater may lead to excessive K+ uptake by grapevines, potentially negatively affecting wine quality.3 However, TMW usually has a high sodium (Na+) and chloride (Cl–) content that can affect soil’s physical, chemical and biological properties. Corrosive metals such as iron (Fe2+) and manganese (Mn2+), often present in municipal wastewater, can clog irrigation equipment. The presence of heavy metals, pathogens and pharmaceutical compounds can also limit the use of TMW since some of these elements can accumulate in plants and ultimately enter the biological food chain.

Methods

Site selection and vineyard characteristics

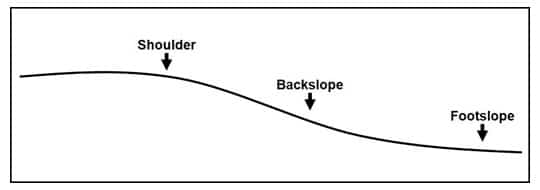

The field trial was carried out in full-bearing, commercial vineyards on a farm near Philadelphia in the Coastal region of the Western Cape from 2006/07 until 2017/18 seasons.4 The region has a Mediterranean climate. Given the hilly landscape where the vineyards were irrigated using TMW, three experimental sites were selected in different landscape positions. The first site was in a Sauvignon blanc vineyard located on the shoulder of a hill (Figure 1) and was planted in 2000. The second and third sites were in two Cabernet Sauvignon vineyards on a back and foot slope. The vineyard on the foot slope was planted in 2001, whereas the one on the back slope was planted in 2002. All grapevines were grafted onto 99 Richter and planted at a spacing of 2.75 m x 1.2 m. The vineyards were managed according to the grower’s standard viticultural practices regarding cover crop, fertiliser and irrigation management.

FIGURE 1. The landscape position of the experimental sites near Philadelphia.

Application of treated municipal wastewater

Each of the three main experiment sites consisted of three treatment plots. Since the study’s primary objective was to obtain a range of soil and grapevine responses to irrigation with treated municipal wastewater, it cannot be regarded as a comparative study. Therefore, there were no treatment replications. It must be noted that several vineyard field trials investigating soil and vineyard responses to irrigation have followed a similar approach.5,6,7 The experimental plots consisted of one row of 15 experiment grapevines, a buffer row on each side and at least two buffer grapevines at each end of the experiment rows. In one treatment, the grapevines were rain-fed, i.e. grown under dryland conditions. It was included to compare soil and grapevine responses upon irrigation with TMW. This was considered a control treatment, given that no raw water was available for irrigation on the farm. Grapevines of the second treatment were irrigated with TMW via a single dripper line (SLD), which is the standard industry norm. Drippers were spaced 1 m apart in the grapevine row and had a flow rate of 2.3 L/h. Irrigation frequency and volumes of water were applied according to the grower’s irrigation schedule. Grapevines of the third treatment received irrigation via double dripper lines (DLD), which doubled the volume of wastewater compared to SLD. The purpose of the DLD was to accelerate any possible effects of the wastewater on the soil and grapevines. Irrigation volumes of the SLD plots were measured by means of water meters from the beginning of the study period. Since the lengths of the DLD plots were the same as the SLD plots, it was assumed that grapevines in the DLD plot received double the volume of irrigation compared to those in the SLD plots.

The TMW was sourced by the farm from the Potsdam Wastewater Treatment Works (WWTW) near the City of Cape Town (CoCT). A sample of the TMW was collected annually on the farm at the beginning of each year (January) from the 2006/07 season. A commercial laboratory analysed the wastewater samples. The water was also assessed for its microbial status from 2008 to 2012.

Results and discussion

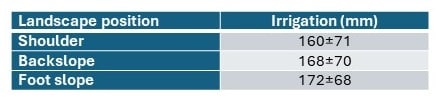

On average, grapevines in the back and foot slope sites received comparable irrigation volumes, whereas those in the shoulder plot received slightly less (Table 1). Due to limited water resources, vineyards in the Coastal region generally receive relatively low irrigation volumes compared to regions such as the Breede and Olifants Rivers. In the latter regions, more water can be abstracted from large irrigation schemes along the rivers. It was previously shown that 129 mm per year was sufficient for drip-irrigated wine grapes near Wellington.8,9 This indicated that the grapevines at Philadelphia received adequate irrigation. On the other hand, it implied that grapevines in the DLD plots were indeed over-irrigated for the purpose of the study.

TABLE 1. The mean volume of TMW applied annually for grapevine irrigation employing single dripper lines near Philadelphia from 2006/07 until 2017/18.

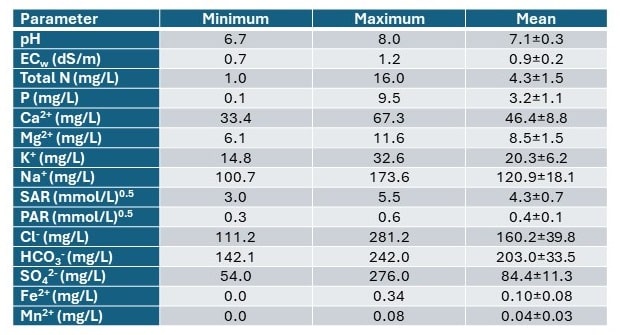

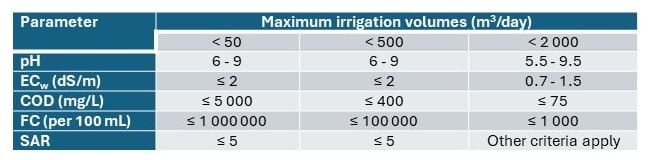

The pH range of the TMW varied between 6.7 and 8.0 throughout the 11-year study period (Table 2). The pH variation was within the range of 6.5 to 8.4, recommended for irrigation water.10 The pH of the TMW was within the legislated limits to irrigate with wastewater as prescribed by the General Authorisations11 given in Table 3. The mean electrical conductivity (ECw) (Table 2) slightly exceeded the critical value of 0.8 dS/m, the salinity threshold for water used to irrigate grapevines.9 Like pH, the ECw was within the legislated limits11 (Table 3). The mean total-N level (Table 2) was below the critical value of 5 mg/L at which crops sensitive to N (such as grapevines) might be affected.9 The P concentration in the wastewater consistently exceeded the long-term critical value of 0.05 mg/L, which demarcates a risk for algal blooms and biofouling of the irrigation equipment.10 Calcium (Ca2+) levels in the wastewater varied between 33.4 mg/L and 67.3 mg/L throughout the 11-year study period (Table 2). The magnesium (Mg2+) levels in the TMW were relatively low. The mean level of K+ in the irrigation water was 20.3 mg/L. The mean Na+ concentration exceeded the critical value of 100 mg/L, the legal limit for irrigating grapevines in South Africa.6

The mean sodium adsorption ratio (SAR) of the TMW (Table 2) also met the criteria stipulated by the General Authorisations11 (Table 3). According to the SAR values of 0 to 10 mmol/L0.5 for grapevines,11 the TMW had a low sodium hazard. The Cl– levels in the TMW (Table 2) were well below the threshold value of 700 mg/L at which toxicity problems in grapevines might occur.9 The levels of HCO3– in the irrigation water ranged between 142.1 mg/L and 242.0 mg/L (Table 2). It should be noted that high levels of HCO3– in irrigation water may negatively impact crops, soils and irrigation equipment.9

The mean COD measured from 2011 to 2018 was 15 mg/L. This met the criteria stipulated by the General Authorisations11 for using wastewater for irrigation (Table 3). The mean E. coli was 27 per 100 mL and was within the legislated limits to irrigate with wastewater as prescribed by the General Authorisations11 given in Table 3. The Fe2+ concentration in the wastewater (Table 2) never exceeded the critical value of 5 mg/L, which is the recommended maximum concentration of Fe2+ in irrigation water used for irrigation of grapevines.12 Levels of Mn2+ in the TMW varied from being absent to a maximum concentration of 0.08 mg/L (Table 2). According to South African guidelines,13 levels of Mn2+ should not exceed 1.5 mg/L since Mn2+ may cause clogging of irrigation pipelines, i.e. similar to Fe2+.

No arsenic (As3+) and mercury (Hg2+) were detected in the TMW from 2008 to 2013. Chromium was present every season up to 2012/13, with concentrations ranging between 0.000 mg/L and 0.023 mg/L. Concentrations of cadmium (Cd2+) and lead (Pb2+) in the TMW were less than 0.003 mg/L and 0.0002 mg/L, respectively. Due to the low concentrations of the heavy metals and the cost implications, analyses of heavy metals were terminated in 2013/14.

TABLE 2. Water quality parameters of the TMW used for vineyard irrigation near Philadelphia from 2006/07 until 2017/18.

TABLE 3. General Authorisations for legislated limits for pH, electrical conductivity (ECw), chemical oxygen demand (COD), faecal coliforms (FC) and sodium adsorption ratio (SAR) for wastewater used for irrigation in South Africa.10

The concentrations of each element applied via the TMW in the vineyard, as well as the amount of irrigation water applied, were used to calculate the amount of each element applied on average SLD plots for the three landscape positions’ plots. Annually, 7 kg/ha, 5 kg/ha and 33 kg/ha of N, P and K+, respectively, were applied. Annual amounts of 77 kg/ha, 14 kg/ha, 201 kg/ha and 267 kg/ha of Ca2+, Mg2+, Na+ and Cl–, respectively, were applied via the irrigations with TWM. The low N content in TMW was insufficient to supply the annual N requirement of grapevines. The TMW provided adequate amounts of P to meet annual grapevine requirements when double the amount of irrigation water was applied. The K+ applied via the TMW irrigation to the DLD treatment exceeded grapevine requirements. The amount of Ca2+ and Mg2+ applied via the TMW also exceeded annual grapevine requirements.

Conclusions

The quality of the TMW used for vineyard irrigation met the minimum criteria stipulated by the General Authorisations for pH, ECw, COD, faecal coliforms and SAR for irrigation with wastewater in South Africa. The P concentration in the TMW consistently exceeded the long-term critical value of 0.05 mg/L, which demarcates a risk for algal blooms in water storage facilities, as well as biofouling of irrigation equipment. The mean Na+ concentration of 120.9 mg/L in the TMW exceeded the critical value of 100 mg/L for irrigating grapevines in South Africa. Chloride levels in the TMW were well below the threshold value of 700 mg/L, at which toxicity in grapevines might occur. Considering the above-mentioned, regular analyses of TMW are essential when using it as an alternative source of water for vineyard irrigation. This will ensure that the legislated limits given in the General Authorisations are adhered to. Furthermore, the analyses will ensure that the chemical load conforms to recommended thresholds and norms. In doing so, irreversible damage to irrigation equipment, soils and grapevines can be avoided.

The low N content in the TMW was insufficient to supply the annual N requirement of grapevines. Where double the normal irrigation volume was applied, TMW supplied adequate amounts of P to meet annual grapevine requirements. The amounts of K+ applied via TMW irrigation to the DLD treatment were more than grapevine requirements and could negatively affect wine quality. The amount of Ca2+ and Mg2+ applied via the TMW also exceeded annual grapevine requirements. In general, using TMW irrigation can supply grapevine nutrients in a plant-available form, but some nutrient amounts may be insufficient, whereas others may be excessive. Consequently, growers are recommended to use an integrated fertiliser program by adjusting fertiliser amounts according to the amount of nutrients applied via the wastewater. Growers could also consider diluting the wastewater with raw water to reduce the oversupply of certain elements if indicated by analysis.

Grapevine and soil responses will be presented in subsequent articles.

Abstract

Low annual rainfall, limited supply of fresh water that can be stored on farms and water restrictions imposed by authorities during drought highlighted the necessity for alternative water sources for vineyard irrigation for the South African wine industry. Therefore, the impact of irrigation with treated municipal wastewater (TMW) on soil and grapevines was assessed under field conditions in vineyards in the Coastal region of South Africa. Grapevines were uninterruptedly irrigated using TMW from the City of Cape Town over 11 years. Grapevines were either rain-fed, irrigated with TMW via a single dripper line, or received twice the volume via double dripper lines. As expected, the quality of the TMW used for the irrigation of the vineyards was below the minimum criteria stipulated by the General Authorisations to irrigate with wastewater in terms of pH, electrical conductivity (ECw), chemical oxygen demand (COD), faecal coliforms and sodium adsorption ratio (SAR). The mean sodium (Na+) concentration in the TMW exceeded the critical value of 100 mg/L for irrigating grapevines in South Africa. However, chloride (Cl–) levels were well below the threshold value of 700 mg/L, at which toxicity in grapevines could occur. The low N content in the TMW could not supply the annual N requirement of the grapevines. The annual amount of P applied via the single dripper lines was slightly below grapevine requirements, whereas double the TMW irrigation applied excessive amounts of P. Amounts of K+ applied via TMW irrigation were more than annual grapevine requirements for the double dripper line treatment, which could affect wine quality negatively. The amount of Ca2+ and Mg2+ applied via the TMW also exceeded annual grapevine requirements. Regular analyses of TMW are essential when using it as an alternative water source for vineyard irrigation. This will ensure that the legislated limits given in the General Authorisations are adhered to and that the chemical load conforms to recommended thresholds and norms.

Acknowledgements

- The project was funded by the Water Research Commission (WRC), Winetech and the Agricultural Research Council (ARC).

- ARC for infrastructure and resources.

- Staff of the Soil and Water Science division at ARC Infruitec-Nietvoorbij for technical support.

- Messrs Pierre Blake for permission to work in his vineyard, and Egbert Hanekom for managing the vineyard and technical assistance.

References

- Du Plessis, J.A. & Schloms, B., 2017. An investigation into the evidence of seasonal rainfall pattern shifts in the Western Cape, South Africa. J. S. Afr. Inst. Civ. Eng. 59, 47-54.

- Hoogendijk, K., Myburgh, P.A., Howell. C.L. & Hoffman, J.E., 2023. Irrigation of agricultural crops with municipal wastewater – A review. S. Afr. J. Enol. Vitic. 44, 31-54.

- Laurenson, S., Bolan, N.S., Smith, E. & McCarthy, M., 2012. Review: Use of recycled wastewater for irrigating grapevines. Aust. J. Grape Wine Res. 18, 1-10.

- Howell, C.L., Hoogendijk, K., Myburgh, P.A. & Lategan, E.L., 2022a. An assessment of treated municipal wastewater used for irrigation of grapevines with respect to water quality and nutrient load. S. Afr. J. Enol. Vitic. 43, 168-179.

- Bruwer, R.J., 2010. The edaphic and climatic effects on production and wine quality of Cabernet Sauvignon in the Lower Olifants River region. Thesis, Stellenbosch University, Private Bag X1, 7602 Matieland (Stellenbosch), South Africa.

- Mehmel, T.O., 2010. Effect of climate and soil water status on Cabernet Sauvignon (Vitis vinifera ) grapevines in the Swartland region with special reference to sugar loading and anthocyanin biosynthesis. Thesis, Stellenbosch University, Private Bag X1, 7602 Matieland (Stellenbosch), South Africa.

- Howell, C.L., Myburgh, P.A. & Hoogendijk, K., 2022b. Use of winery wastewater as a resource for irrigation of vineyards in different environments. WRC Report No. 2651/1/22. ISBN 978-0-6392-0341-6.

- Myburgh, P.A., 2011a. Response of Vitis vinifera cv. Merlot to low frequency drip irrigation and partial root zone drying in the Western Cape Coastal region – Part I. Soil and plant water status. S. Afr. J. Enol. Vitic. 32, 89-103.

- Myburgh, P.A., 2011b. Response of Vitis vinifera cv. Merlot to low frequency drip irrigation and partial root zone drying in the Western Cape Coastal region – Part II. Vegetative growth, yield and quality. S. Afr. J. Enol. Vitic. 32, 104-116.

- Howell, C.L. & Myburgh, P.A., 2013. Permissible element concentrations in water used for grapevine irrigation (Part 1) – pH, N, P and cations. Winetech Technical Yearbook 2013, 56-58.

- Department of Water Affairs (DWA), 2013. Revision of general authorisations in terms of Section 39 of the National Water Act, 1998 (Act No. 36 of 1998), No. 665. Government Gazette No. 36820, 6 September 2013. DWA, Private Bag X313, Pretoria 0001, South Africa.

- Van Zyl, J., 1981. Irrigation (in Afrikaans). In: Burger, J.D. & Deist, J. (eds). Wingerdbou in Suid-Afrika. ARC Infruitec-Nietvoorbij, Private Bag X5026, 7599 Stellenbosch, South Africa.

- Department of Water Affairs and Forestry (DWAF), 1996. South African water quality guidelines. Vol. 4. Agricultural use: Irrigation. CSIR Environmental Services. DWA, Private Bag X313, Pretoria 0001, South Africa.

For more information, contact Carolyn Howell at howellc@arc.agric.za.

Click here to get your copy of WineLand Magazine and here to subscribe to our newsletter.